Steam

System in petrochemical processing and Refinery

Steam system may be the most essential among

utility systems in chemical, petrochemical and refinery plants. It is widely

used in various applications. Because of its important magnitude, I decide to

introduce this system applied in plant with the purpose of helping process

apprentices to get the basic concept about steam application, supporting their

design works as well as operation.

Purpose and

Application

Thank to several advantageous properties,

steam is universally employed to support many processes occurring in

manufacturing. It plays an important part and is indispensable to keep the

plant operating smoothly. The purpose of steam is to provide heat and power.

Main applications maybe are as follows:

Steam for heat exchanger,

steam for stripping, cracking steam in refinery, heating steam for reboiler or

process vessel, steam for mechanical driver (e.g. turbine), steam tracing,

steam air decoking of heater, steam for smokeless flare…

It is used continuously or intermittently.

Steam

Distribution Level

To serve several service effectively, steam

is generally divided into three levels:

-

High pressure steam: ~2.0-4.1 Mpa, gauge

-

Medium pressure steam: ~ 1.1 Mpa, gauge

-

Low pressure steam: ~0.3 Mpa, gauge

Sometimes steam system may consist of more than above levels

depending on specific application.

One principle that needs to keep in mind is: using low

pressure steam in heating services wherever possible.

Superheated

steam

One term we must pay attention is superheated steam.

Superheated steam is steam heated to a temperature higher

than the boiling point corresponding to its pressure. It is needed to

distinguish with saturated steam, steam at the temperature of the boiling

point which corresponds to its pressure

point which corresponds to its pressure

Superheated steam has advantage of economical transportation

so that it is used to distribute throughout plant. Frequently steam is

superheated from 55 ℃to 195℃above saturation temperature

in steam coils located in the inlet portion of the boilers convective section.

When necessary it is desuperheated (reduce heat) to best

suite requirement as well as protect equipment from damage due to high

temperature. This process is carried out through an equipment called

Desuperheater.

Desuperheating is accomplished by atoming fluid

and cooling fluid. Cooling fluid is employed to reduce temperature of

superheated steam whereas atomizing fluid is needed when the pressure of the

system is not enough to make cooling fluid atomize.

Fig.2 Steam Network in a petrochemical plant

Steam Network System

To fully understand about how steam system work, please refer

to Fig. 2

In this network, steam system composes of three level: High,

medium and low pressure steam. High pressure steam coming from boiler is

desuperheated before going to high pressure-needed users. Desuperheating is

implemented by boiler feed water. Steam after used become to condensate (maybe

liquid or two phase). It is collected in flash drum. Flash drum has a duty to

separate entrained steam and condensate. One part of high pressure steam is

letdown to medium pressure steam by a control valve. Before coming to user, it

is also desuperheated prior to combining with steam from flash drum. Low

pressure steam is generated in the same way from medium pressure steam.

Condensate from the whole system goes from the last fresh drum to condensate

storage.

Steam

Generation System

Feed sources

Steam is generated in boiler from Condensate and Boiler Feed

Water.

Condensate

After steam come to users it loose heat and become

condensate. Condensate is recovered whenever economically justified and

returned to the deaerator as boiler feed makeup. Frequently the returned

condensate must be treated to remove dissolved and insoluble iron contaminants

before it is acceptable as feed.

Boiler Feed Water.

Boiler feed water is obtained from treating raw water. The

purpose of treating raw water is to remove impurities and metal cations that

may cause corrosion and fouling for the system.

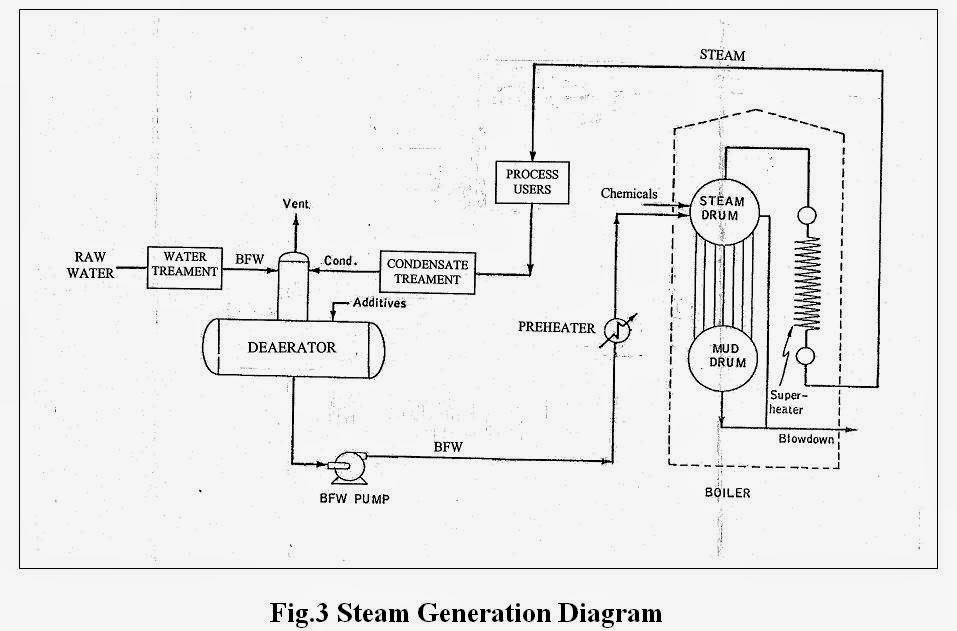

System configuration

Please refer to Fig.3

for the system detail.

Boiler: Main

equipment of the system where steam is generated. Saturated steam leaving Steam

Drum is superheated in team Superheater. Chemicals are injected into Steam Drum

to concentrated the dissolved solid. To maintain the boiler water solids at an

acceptable concentration, a blowdown stream is continuously withdrawn from Mud

Drum and Steam Drum.

Deaerator: This

equipment is in charge of oxygen and carbon dioxide removal. If these entrained

gases present in water feed are not completely removed in the deaerator, the

resulting boiler feed water is aggressive and may cause severe corrosion of

boiler feedwater pump internals at areas of turbulence or high pressure drop.

Water feed is also preheated here to reduce boiler fuel consumption.

Pump: Responsible

for transfer water from Deaerator to Boiler. It also creates pressure high

enough for boiler requirement.

Preheater: To get

efficiency and save fuel for boiler, feed is further heated to partly turn

water feed into steam before being introduced into Steam Drum.

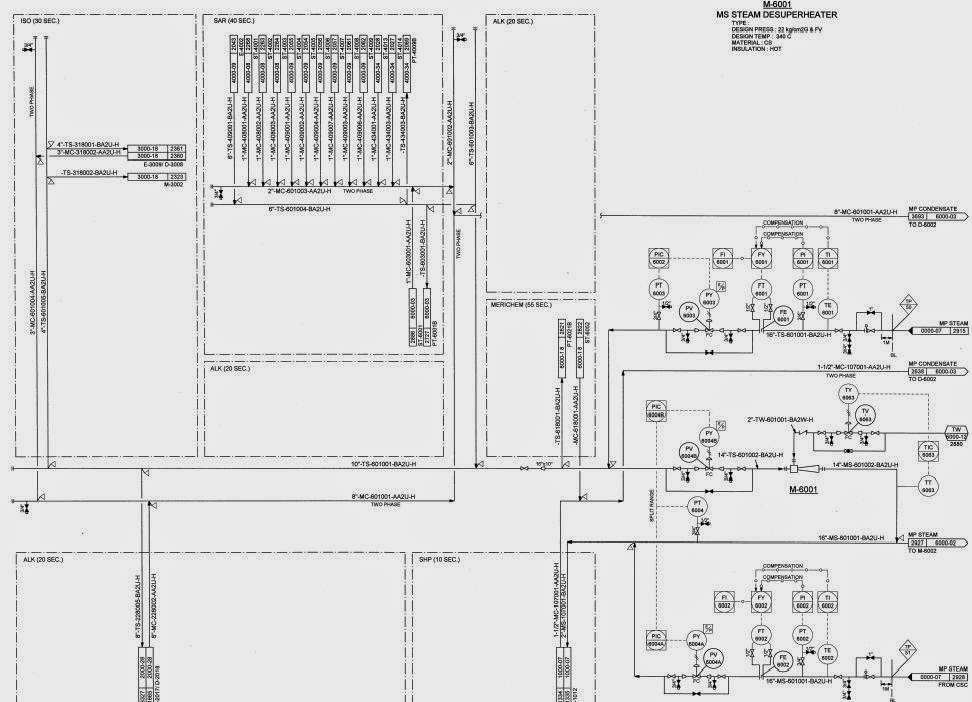

Finally, please refer to Fig 4 for overall view and detail

about steam system in plant. This sample Process Flow Diagram is taken from a

refinery.

Conclusion

It is difficult to mention all aspects of steam system in the

framework of this article. About specific information and system design guide I

will introduce in another time. However, with the concept knowledge presented

here I hope that it is useful to provide direction for new process engineer who

wish to get approach for system design in which steam is a system impossible to

be neglected.

Fig.4 Steam

System Diagram in Refinery